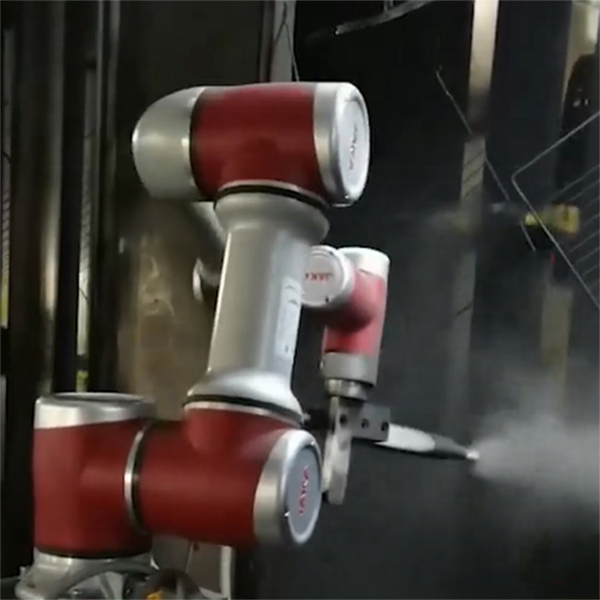

JAKA Zu 3 Collaborative Robot

Technical features

|

Payload |

3 kg |

|

Weight (W cable) |

12 kg |

|

Working Radius |

626 mm |

|

Repeatability |

±0.02 mm |

|

Axis |

6 |

|

Programming |

Graphical I Visual |

|

Teach Pendant |

MT(PAD/Mobile)APP |

|

Collaborative operation |

In compliance with GB 11291.1-2011 |

|

Certifications |

CR, CE, 15066 |

Specifications

|

Rated Power |

150 W |

|

Temperature Range |

0-50℃ |

|

IP Level |

IP54 |

|

Tool I/O Power |

24 V |

|

Tool I/O Size |

M8 |

|

Base Diameter |

129 mm |

|

Installation |

At any angle |

|

Material |

Aluminum, PC |

|

Tool I/O |

Digital input 2/Digital output 2/Analog input 1 |

|

Cable Lenght |

6 m |

|

Package Size |

460×375×365(mm) (L×W×H) |

Scope and speed

|

Robot |

Workscope |

Max Speed |

|

Joint 1 |

±360° |

180°/s |

|

Joint 2 |

-85°,+265° |

180°/s |

|

Joint 3 |

±175° |

180°/s |

|

Joint 4 |

-85°,+265° |

220°/s |

|

Joint 5 |

±360° |

220°/s |

|

Joint 6 |

±360° |

220°/s |

|

Max Speed |

/ |

1.5 m/s |

Control cabinet

|

Robot |

Workscope |

Max Speed |

|

Joint 1 |

±360° |

180°/s |

|

Joint 2 |

-85°,+265° |

180°/s |

|

Joint 3 |

±175° |

180°/s |

|

Joint 4 |

-85°,+265° |

220°/s |

|

Joint 5 |

±360° |

220°/s |

|

Joint 6 |

±360° |

220°/s |

|

Max Speed |

/ |

1.5 m/s |

The Many Features of JAKA MiniCobo

Innovative breakthroughs from drag programming to wireless connection continuously led the trend of robotics development

Graphic Programming

Anyone can teach this cobot; no programming experience necessary. Intuitive, user-friendly software helps guide the process.

friendly software helps guide the process.

Drag Teaching

Teach the cobot what to do, simply by dragging it to desired positions. Defined by 6 axis points, the position will be memorized.

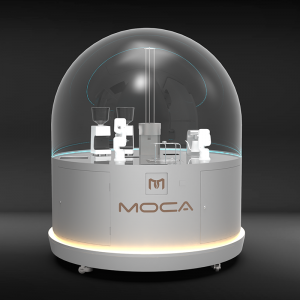

Plug and Play

The installation of our cobots is fast, easy, and flexible. They may be mounted at any angle, and will begin working immediately once placed.

Wireless Connection

The wireless technology of the JAKA Zu 3 makes it one of the most convenient-to-use robots around.

No Teach Pendant

JAKA APP is available on tablet PC, mobile phones, PC, by which you can use to interact with JAKA Cobots.

Remote Monitoring

The cobot may be programmed regardless of geographical location. The monitoring system can give instant feedback on tasks, or raise alerts, over the web.

Best Applications for JAKA Zu 3

Whether it’s inspection, polishing, assembly or otherwise, the JAKA Zu 3 cobot applications is on-hand to assist with factory automation

Gluing and Bonding

Electronics Assembly

Inspection

Pick and Place

Screw Driving